by

Gus Iversen, Editor in Chief | October 30, 2017

From the October 2017 issue of HealthCare Business News magazine

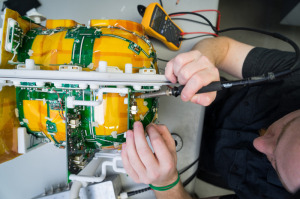

An MR image is only as good as the coils used to acquire it. For that reason it’s imperative that providers take excellent care of them and ensure they are working correctly.

As technical innovations occur, these complex systems are being designed with more resonating elements in increasingly ergonomic housing. According to Randy Jones, president and CEO of ScanMed, that leads to increased electronics miniaturization, incorporation of high density coil-system cables, new sealed housing materials such as ultraflex foam products and proprietary high density control circuitry and preamplifiers – all of which contribute to the sophistication of coils, as well as the challenges of servicing them.

“This raises the bar for coil service companies to have the electronics engineering skills to decipher and diagnose these circuits and source their parts,” says Jones. “They also must significantly broaden the scope of their capabilities to include plastics reconstruction, painting, foaming and coat processes, and then purchase large quantities of special MR cable material in order to replace those broken system cables.”

Ad Statistics

Times Displayed: 45704

Times Visited: 1370 MIT labs, experts in Multi-Vendor component level repair of: MRI Coils, RF amplifiers, Gradient Amplifiers Contrast Media Injectors. System repairs, sub-assembly repairs, component level repairs, refurbish/calibrate. info@mitlabsusa.com/+1 (305) 470-8013

The toll this takes on service and repair companies should send a message to end users: take good care of your coils to avoid potentially elaborate and costly repairs.

“We see some OEMs using newer style connectors that not all coil repair vendors are able to repair or replace if they break,” says Pat Fitzgerald, executive vice president and general manager of Richardson Healthcare. “This is why it’s important to consider repair technology trends, too, such as 3-D printing, which makes some repairs or refurbishment much easier.”

HealthCare Business News reached out to a range of servicers and refurbishers in the coil industry to get a better understanding of how these essential tools are evolving, what tips they have to ensure an MR coil is capturing high quality images for the maximum period of time and when it’s time to replace a coil instead of getting it repaired.

The challenge of sophisticated coils

While coil technology has fundamentally remained the same, Wes Hershberger, a customer service representative with MRIcoilrepair.com, says new methods of RF signal delivery through digital conversion within the coil itself have brought new opportunities in imaging, as well as a greater need for comprehensive approaches to repairing coils electronically.

Other experts echoed that sentiment, such as Bruce Berry, service manager with Advanced Imaging Solutions, and Adam Band, president of Band Medical Industries, who both say coils are becoming increasingly sophisticated, with more channels being added and additional flexible array options.